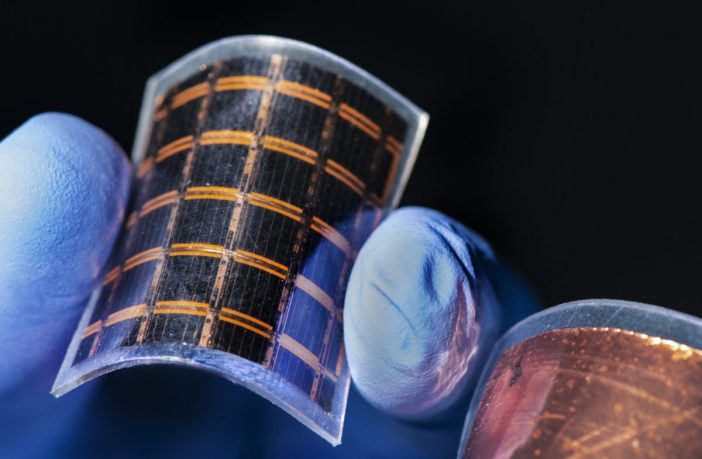

- Scientists from Chalmers University of Technology in Sweden have shown how to recycle valuable metals like silver (Ag) and indium (In) from flexible CIGS solar cells using mild leaching conditions.

- They used 15.6 cm2 x 15.6 cm2 flexible CIGS solar cells with an Ag conductive grid and stainless-steel substrate from Swedish PV manufacturer Midsummer AB.

- Each cell was cut into eight identical pieces and then each sample was cut further into one small and one big piece.

The academics placed the small pieces of the PV cells into perfectly sized digestion containers to obtain the total amount of silver and indium per cell. They placed the bigger piece in leaching containers and filled both kinds of containers with a desired volume of nitric acid (HNO3) solution of a specific concentration. The geometrical surface area to liquid ratio (A:L) was also varied across experiments. The team performed all the experiments at room temperature and with a stirring rate of 200 rpm.

After showing that both silver and indium fully dissolved during digestion, and therefore that the leaching experiments would be conducted with the cells’ complete amount of each element, the scientists set out to test what concentration of nitric acid and what ratio of geometrical surface area to liquid resulted in the highest leaching yields.

Results show that a concentration of nitric acid of two moles and a 1:3 A:L ratio leads to very high recovery rates for silver and indium. After four to six hours of leaching, around 90% of silver is recovered, and after 24 hours the recovery rate hits 100%. Around 20% to 25% of indium is recovered within the first hour of leaching, and the highest yield of 85% is achieved after 28 hours.

“When comparing all the results for the different experimental conditions it can be said that the high yields of Ag and In are always accompanied by high contamination levels from many other elements, with [Zinc] being always present,” the scientists noted, adding that contamination with molybdenum can also be problematic.

The scientists also noted that their method isn’t yet appropriate for industrialization, as the concentrations of silver and indium are too low to be used directly in a feasible purification process using more than 1 gram per liter. “Some means of up-concentrating, for example by a reuse of the same leachate for multiple cells, should be considered for industrialization,” they concluded.

The team shared their findings in “Valuable metal recycling from thin film CIGS solar cells by leaching under mild conditions,” which was recently published in Solar Energy Materials and Solar Cells.

Author: Beatriz Santos

This article was originally published in pv magazine and is republished with permission.