Newsflash

- University College London researchers have said in a new study that the pumping of hydrogen into gas networks poses risks and requires a rethinking of usual blending techniques.

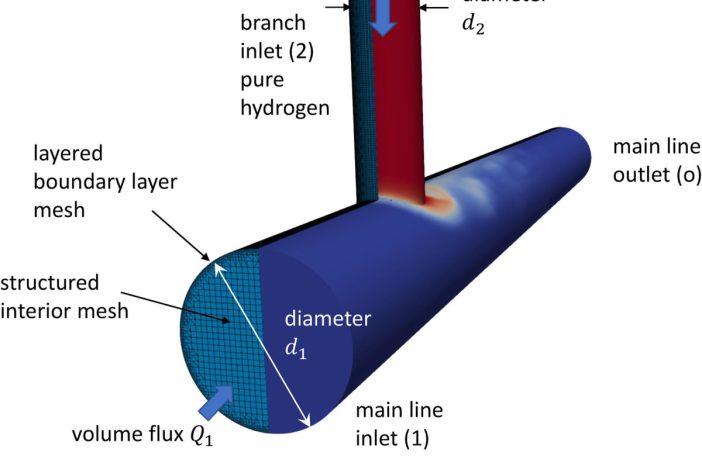

- They found that injection of hydrogen through a T junction leads to poor mixing and high concentrations of hydrogen on pipe walls plus stratification leads to higher hydrogen concentration near upper pipe wall.

- Higher hydrogen concentration on walls leads to the embrittlement of high-tensile steels.

“The strongly inhomogeneous distribution of hydrogen within the pipe flow and on the pipe walls could indicate the location of potential pipe material degradation, including embrittlement effects of gas pipelines,” the researchers said in the International Journal of Hydrogen Energy.

They focused on the common blending method, based on the injection of hydrogen through a side branch into a main gas header pipe (T-junction). “The low molecular mass of hydrogen reduces the penetration of a side-branch flow and increases the buoyancy forces leading to stratification with high hydrogen concentrations on the upper pipe surface, downstream of the branch,” the team said. “Top-side injection leads to the hydrogen concentration remaining >40% for up to eight pipe diameters from the injection point for volumetric dilutions less than 30%. Under-side injection promotes mixing within the flow interior and reduces wall concentration at the lower surface, compared to top-side injection.”

Link to the full paper HERE

Author: Bryan Groenendaal