Albert Einstein did not win his Nobel prize for his work on relativity. He won it for his paper on the photoelectric effect: “On a Heuristic Viewpoint Concerning the Production and Transformation of Light”. The paper was written in 1905 but it was not until 1921 that he was awarded his Nobel prize for his groundbreaking work. It was around this time that folk started to recognise the potential of photovoltaics. Photo means ‘light’ and voltaic means ‘electricity or electrical current’.

Solar photovoltaic panels are made of silicon, a common element found on our planet. The silicon is formed into a series of extremely thin wafers which are mounted on a backing board. The board is framed and the sun-facing surface encased in glass.

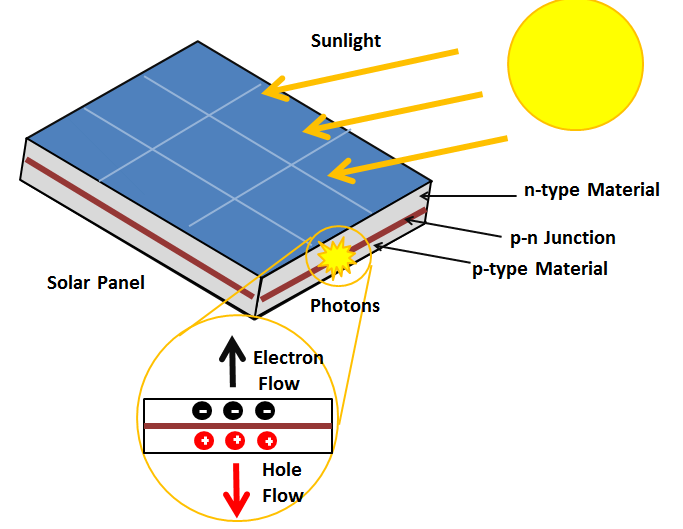

The silicon wafers are around 100mm x 200mm square in size and extremely thin measuring on average 16 μm (the μm symbol stands for micrometer or micron which is one-millionth of a meter). The wafers consist of two layers. The top layer consists of strips of negative type silicon, which has an extra electron. The bottom layer consists of positive type silicon, which is missing one electron. The two are combined to form a photovoltaic cell.

During manufacturing, small amounts of other elements are introduced to alter the electrical charges of the silicon atoms. The magic happens when the sunlight strikes the wafers. Sunlight is a form of energy consisting of invisible particles called photons. When photons are exposed to the silicon wafers, heat is generated which excites the electrons causing some to break free.

When this happens, the negative type silicon electrons seek out the ones in positive type silicon to replace the missing electrons within their atoms. An electrical current is then produced by the movement of these electrons. Silicon has semi semiconductor qualities which ensure that constant electron imbalances are sustained. This means that the solar electricity supply is continuous as long as the photons are striking the silicon wafers.

Diagram: The photovoltaic effect

Each wafer is connected in series to produce a combined current for a single panel. Each panel is then also connected to form a string. The more panels in the string, the greater the electricity output. The cable from each string is then fed to a combiner box ready to be converted.

The current produced from solar panels is direct current (DC) which is converted into alternating current (AC) using an inverter. Once the inverter has done its job, the electricity is ready for use at a standard 220V which matches the grid supplied power to your home.

The power produced is variable because it depends on the movement of the sun. The output resembles that of a bell curve starting low at sunrise, peaking at midday and declining at sunset. Factors such as seasonality, angle or tilt, shade, cloud cover, dust and orientation (in South Africa, a northerly orientated mounting produces the best results) all affect the performance output of the panel.

So the genius of Albert Einstein shines to this day and he would be very proud to know that photovoltaic technology is widely deployed throughout the world plus outer space. He would be even more impressed in the robotic technology used in production and the fact that components that make up a solar photovoltaic panel are recyclable. Even the silicon wafers can be recycled after their life and re-manufactured to again produce electricity.

Author: Bryan Groenendaal