- While not all plastics are being recycled, even the ones that display the recycling sign, the global plastic waste problem is nowhere close to being resolved.

- Recycling, generally determined by factors like demand, legislations, and economy, takes on arguably around 20% of the annual production of plastics, leaving a large quantity unattended, doomed to last forever in our environment.

- In addition, competing with newly-produced materials, recycled plastics need to meet standards of quality and price, and undergo a sustainable, efficient, and economically viable transformation.

ROGP or Rejects of Glass & Plastics Technology is an innovative approach that repurposes plastics, once labeled as non-recyclable materials due to technical complexity or economy-related issues

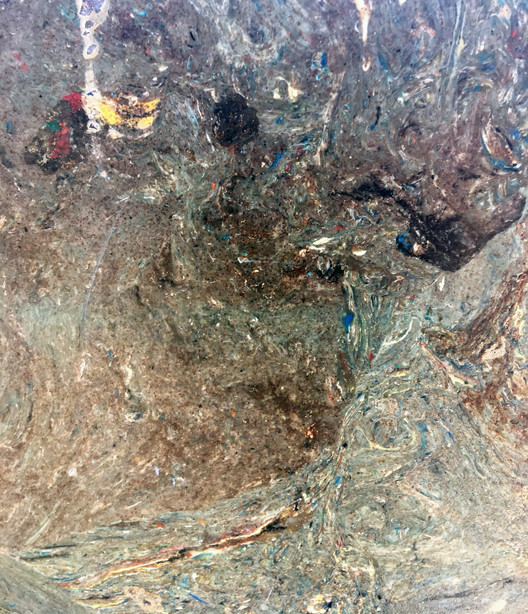

Offering a solution that meets technical, environmental and economic requirements for sustainable use of all 80+ types of plastic waste, including mixed plastics, this particular ROGP technology recycles plastics (all 7 major plastic codes) and glass (all types of glass) into a “durable and price competitive new material which has numerous applications”, especially in the construction industry.

Current global challenges with existing recycling technologies include the impossibility to process mixed plastics due to their chemical composition, the need to segregate the materials and establish different recycling lines, the high energy consumption as well as the cost. Moreover, for glass, considered infinitely recyclable, low recycling rates are due to sorting difficulties, transportation obstacles, and expensive processes. On that note, ROGP, operated by Development Inc., is one single technology that can at the same time, recycle all 80+ types of plastics and all types of glass, and generate a composite from the rejects of glass and plastic.

The process builds on turning environmental liabilities into abundant resources, with a significant cost advantage over alternative materials. It requires no washing of plastics and glass; and it can handle all types of plastics, including mixed plastic waste and all types of glass, including mixed color and glass with impurities.

This efficient and low-cost recycling method has the ability to produce a multitude of end-products, from construction, infrastructure, piping, to urban furniture. Final outcomes are extremely diverse, especially that it can be molded into a variety of shapes and colors. Actually, specifications can be altered depending on the intended application. It can be used for tiles, speed bumps, parking stops, water pipes ducting, street furniture, waste sorting bins, building facade finishing, etc. Durable, flexible, strong, and with a relatively low production cost, this technology can also create a substitute for natural resources.

More key features of the technology include:

Positive Environnemental Impact

- Infinitely recyclable

- Energy-efficient process

- Negligible micro-particle loss

- Minimal air pollution and CO2 emission

Low Production Cost

- 40% cheaper than wooden boards

- 50% cheaper than resin

- 70% cheaper than granite

Mechanical properties

- Flexural strength: 13.9 Mpa, ref (ASTM D 790M-93)

- Compressive strength: 11.67 Mpa, ref (ASTM D 695M-91)

- Abrasive Resistance: loss of 0.21mm after 1000 revolutions, equipment utilized (Tinius Olsen WearometerC.D.R)

- Absorption Capacity:0.05% by weight, ref (ASTM D 792-9L)

- Density: 1.022 g/cm3 expressed in Dry Unit Weight, ref STMASTM D-570-95) (A

- Wet-Dry Test: 0.0176% loss, ref (ASTM D5313)

- Sodium Sulfate/Magnesium Sulfate Soundness Test: zero loss, ref (ASTM D5240)

Author: Christele Harrouk

This article was first published in Arch Daily and is republished with permission.